Main I&C/Radiation Monitors: Difference between revisions

(No difference)

|

Revision as of 17:00, 20 August 2025

This wiki provides an overview of Radiation Monitors and outlines existing guidance documents for the Radiation Monitoring System (RMS). It also details a review of recent industry issues with the RMS and guidance that was developed in response to these issues.

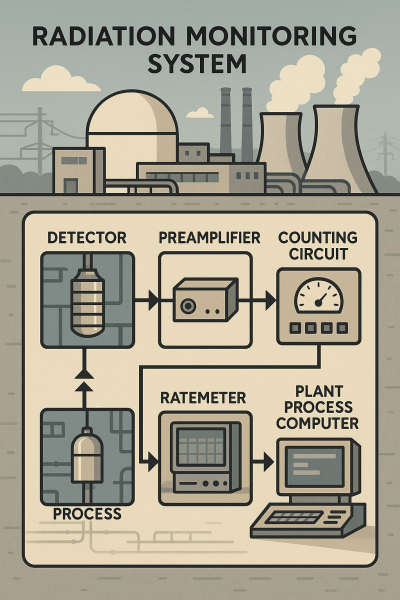

The Radiation Monitoring System (RMS) in nuclear power plants measures the radiation or activity levels in various process streams and areas. Radiation monitors continuously measure radiation levels in key areas of the plant including containment, spent fuel pool, and effluent discharge points. They also provide alarms and/or automatic actions if limits are exceeded.

The radiation monitoring system is comprised of two subsystems, process monitors and area monitors.

Area radiation monitors measure ambient radiation levels in various plant locations where exposure could occur due to normal operations or abnormal events. They provide early warning during abnormal or changing radiological conditions.

Process radiation monitors measure radioactivity within plant systems. They monitor process liquid and gas flows as well as liquid and airborne effluents. The process radiation monitors provide early warning of an off-normal event or plant malfunction, warn personnel of abnormal radiation levels, and prevent inadvertent release of radioactivity into the environment.

System Description[edit]

Area Radiation Monitors[edit]

Area radiation monitors are installed at key locations throughout the facility, including the control room, containment building, and other designated areas or rooms within the plant. The area radiation monitors provide continuous indication of background radiation and alert plant personnel when radiation thresholds are exceeded. The alarms associated with area radiation monitors include annunciators in the control room as well as local alarms.

The area radiation monitoring system consists of multiple detection channels, each assigned to a specific physical zone within the facility. These channels are equipped with individual radiation detectors that continuously monitor and display dose rates for their designated areas. Indication for the area radiation monitors is normally in the control room, and based on design, may have local indication as well. The detectors generally used for area monitors are Geiger-Mueller (G-M) tubes, beta or gamma scintillation detectors, and ion chambers.

Containment/Drywell High Range Area Radiation Monitors are designed to measure extremely high radiation levels that may occur during severe accidents, such as a loss of coolant accident (LOCA).

Process Radiation Monitors[edit]

The process radiation monitoring system monitors the radiation level of plant process liquid and gas streams. These monitors indicate the radioactivity of the process stream and alert personnel when operational limits are approached for the normal release of radioactive material to the environment. They also alert personnel to off-normal conditions, such as leakage from a contaminated system to a clean system or indications of failed fuel. Additionally, process radiation monitors monitor effluent release points during and after accident conditions. Process radiation monitors may also provide automatic isolation functions, such as closing of vent valves or discharge valves, based on application.

Process radiation monitors can be in-line or off-line monitors. In-line monitors have the detector probe directly in the process stream. Off-line monitors take suction off the process stream and pass the flow to the detector, then returning the sample.

RMS Industry Issues[edit]

NRC IN 2013-13 R1 - Deficiencies with Effluent Radiation Monitoring System Instrumentation[edit]

The U.S. Nuclear Regulatory Commission (NRC) issued Information Notice (IN) 2013-13 Revision 1, “Deficiencies with Effluent Radiation Monitoring System Instrumentation” in 2015. This IN was issued to inform U.S. licensees of operating experience with radioactive effluent monitoring systems that was reviewed from 2007 through 2012. The review identified issues with Radiation Monitoring Systems regarding design modifications, calibration, representative sampling, and maintenance. The NRC identified 27 occurrences of system degradation that warranted an inspection finding or violation, 11 of which are provided as examples in the IN.

CHEM 2023-018 Lessons Learned from Issues Affecting Radiation Monitors[edit]

Since the issuance of NRC IN 2013-13 R1, there have been additional RMS-related events significant enough to warrant an NRC finding or violation. Due to the relatively high number of findings related to Radiation Monitoring Systems, EPRI conducted an analysis of the events 2013 to 2023 to identify technical issues or insights that may warrant additional guidance to improve industry performance in this area. CHEM 2023-018 “Lessons Learned from Issues Affecting Radiation Monitors” provides a summary of issues associated with plant radiation monitors that are relied upon to implement a site emergency plan, along with lessons learned and recommendations to prevent their occurrence. The issues were documented in notices of violations given to licensees over the past 10 years by the U.S. NRC and are associated with challenges to the calibration, maintenance, and use of radiation monitors. Three causal factors were identified that contributed to most of the findings reviewed:

- The ties between the RMS and plant processes/programs are not well understood.

- The ownership of the site RMS is not clearly defined.

- The knowledge of, and expertise with, their RMS has declined over time.

CHEM 2023-018 outlines general recommendations, including the assignment of a dedicated system owner for the RMS and instruction on the dependency of site programs (e.g. emergency plan) on the system’s capabilities and functionality. It also recommends implementation of targeted training for applicable personnel—such as operations, maintenance, engineering, radiation protection (RP), and emergency preparedness (EP) staff—who require an understanding of how the RMS integrates with site programs and processes under both routine and emergency conditions. The document also details specific recommendations based on the technical issues identified in the events. It was identified that there was a need for further topical guidance based on these recommendations and the following RMS whitepapers were developed.

RMS Topical Guidance Whitepapers[edit]

| Title | Description |

|---|---|

| CHEM 2024-006 Radiological Monitoring Topics During Accident Conditions (draft under review) |

Reviews regulatory guidance resulting from the Three Mile Island (TMI) event related to the radiological monitoring topics (NUREG-0737):

Provides detailed guidance and recommendations to enhance radiological monitoring during accident conditions and ensure compliance with the regulatory guidance. |

| CHEM-2024-007 Vendor Information that Supports Nuclear Power Plant Radiation Monitoring Systems |

Outlines vendor information related to RMS equipment that should be available as part of a licensee’s RMS program. Describes the regulatory basis applicable to RMS instrumentation and the continuing importance of the original equipment manufacturers (OEM) qualification. Details OEM documentation on the system and explains how those materials support its functionality. Reviews considerations for addressing missing OEM data. Provides a vendor documentation checklist. |

| CHEM-2024-008 Assessment Plan for Radiation Monitoring System (RMS) Instrumentation and Maintenance |

Tool to guide an RMS vulnerability assessment. Provides an overview of elements included in an assessment plan of a site’s RMS. Reviews the installation, maintenance, calibration, and operating conditions and bases of the installed RMS equipment. Results from the assessment verify and/or provide feedback and recommendations to ensure that the RMS equipment and programmatic support meet regulatory requirements and industry practices. |

| CHEM-2024-009 Radiation Monitoring System Health Metrics |

Tool to assist system owners with:

Provides expanded technical guidance on maintaining system health metrics for the Radiation Monitoring System (RMS). Details a baseline template of system metrics and indicators specific to maintaining the reliability of the RMS. Documents example industry RMS scorecards. |

| CHEM-2024-010 Configuration Control of Radiation Monitoring System Databases |

Provides guidance and recommendations related to the configuration control of radiation monitor system (RMS) databases. Describes essential approaches and elements of RMS-related programs that support effective administration and maintenance of RMS databases. Identifies activities that impact the RMS database. Discusses training and knowledge transfer, use of an RMS steering committee, and cross-functional reviews. Describes high-level procedure controls for the RMS Database. Documents an example industry procedure for database configuration control. |

| Radiation Monitor Calibration and Source Utilization: Key Concepts and Definitions (draft under review) |

Addresses the knowledge gap identified in CHEM 2023-018 on source usage, specifically focusing on source selection and calibration processes. |

| Radiation Monitor Replacement Change Management (draft under review) |

Provides a change management template for use in conjunction with existing engineering processes and procedures, to facilitate necessary cross-disciplinary impact reviews. Provides technical guidance and lessons learned from industry operating experience associated with radiation monitor replacements. |

EPRI Guidance on Radiation Monitoring Systems[edit]

RMS Guides[edit]

EPRI has published three guidance documents for managing and maintaining reliability of the RMS. The existing RMS guidance outlines the foundational principles and requirements for system operation and maintenance. The newly developed RMS whitepapers complement these documents by offering refined methodologies, current technical insights, and implementation strategies. When used together, these resources provide a cohesive and up-to-date framework to support effective system performance.

| Title | Description |

|---|---|

| Area and Process Radiation Monitoring System Guide |

This guide discusses the Radiation Monitoring System (RMS) and the major components that are used to measure radioactivity in nuclear power plants. It describes the various applications of radiation monitors and the international and domestic requirements that must be met by the RMS. It also provides an overview of maintenance practices and reliability improvements for the system. |

| Calibration of Radiation Monitors at Nuclear Power Plants |

This report provides guidance and requirements for tertiary/transfer calibration and primary calibration of radiation monitor detector channels at nuclear power plants. It describes the different types of detectors used in the RMS and the elements of calibrations. The guide summarizes the licensing bases and requirements for radiation monitor calibrations. It also provides guidance on trending performance and details operating experience with RMS calibrations. |

| Radiation Monitoring Systems Obsolescence Management Guide |

This report is a comprehensive guide for upgrading and managing obsolete Radiation Monitoring Systems. It provides recommendations on upgrading the systems and developing bridging strategies based on industry experience. |

Industry Experience[edit]

This section presents a collection of technical reports that illustrate industry experience and applied research relevant to the Radiation Monitoring System (RMS).

| Title | Description |

|---|---|

| Utility Experience With Major Radiation Monitoring System Upgrades |

This report summarizes utility experience in planning and implementing major upgrades to the RMS. Included is information on utility work practices, procedural controls, financial aspects of upgrades, and cost accounting approaches. |

| High Range Radiation Monitor Cable Study: Phase I |

These reports describe the thermally induced current (TIC) study for High Range Radiation Monitor cables. Phase I of the study confirmed the existence of thermally induced currents and found that they were of significant amplitude and duration to be of concern. Phase II analyzed the source of the currents, developed a model for the phenomenon, developed a prototype electronic fix, and provided examples of analyses of the TIC response in order to design basis event thermal profiles. |

| Life Cycle Management Planning at V.C. Summer Nuclear Plant: Main Condenser, Radiation Monitoring System, and Nuclear Safety-Related HVAC Chilled Water |

This report provides the industry with lessons learned from applying the EPRI LCM planning process to three SSCs at V.C. Summer Generating Station. Part 2 of the report describes the LCM plan for the Radiation Monitoring System. |

Training[edit]

Radiation Monitoring System (RMS) Computer Based Training (CBT)

This CBT presents an overview of the Radiation Monitoring System used by nuclear power facilities. It describes the components of RMS area and process monitors and a variety of related topics including maintenance, calibration, operational issues, compliance, and equipment obsolescence.

References[edit]

- Westinghouse Technology Systems Manual Section 16.0 Radiation Monitoring System

- Radiation Monitoring Systems USNRC Technical Training - Radioactive Waste Management

- NRC Information Notice 2013-13, Rev. 1: Deficiencies with Effluent Radiation Monitoring System Instrumentation

- NUREG-0737 Clarification of TMI Action Plan Requirements

Record of Revisions[edit]

| Number | Date | Description of changes |

|---|---|---|

| 0 | August 2025 | Initial release |